RFID application in retail supply chain

In recent years, radio frequency identification (RFID) applications have been seen as one of the technologies that change human consumption chain, and they have been used in our daily life such as swipe cards and ETC gift cards. For the past few years, RFID technology continue to improve which make the RFID tags becomes easier to apply and widely used in different areas. There are few points for how to efficiently use RFID tag in the supply chain process, which can be easily maintained on trackable supply chain.

First of all, define the goods/services that need use RFID tags. Nowadays there are many products using RFID tags such as denim, cosmetics, transportation boxes, footwear, drugs, etc. Some organizations, such as ARC-RFID Labs at Auburn University, have released RFID inlays and global GS1 TIPP classifications. EECC’s TACTA has significantly improved RFID tags’ testing and certification in different areas. For example, retailers and clothing manufacturers are now able to purchase M tags, which have been certified and can be used for services and footwear category.

Where are the goods will be stored and tracked? When select labels/tags, environmental circumstances should be taken into account, such as density, metal content, liquid or glass, and so on. RFID is now commonly used in retail stores, factories and distribution channels. In addition, it is necessary to take into account the product’s package quality.

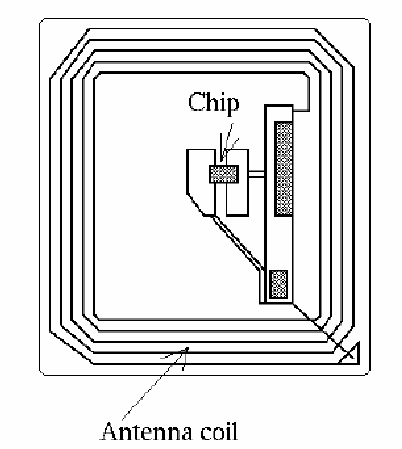

The labelling and coding process. Many IC chip manufacturers such as Impinj, NXP (NXP) and Alien Technologies, etc., has improved the data reading and write sensitivity. The selection of chip, optimized antenna design and system-level testing will ensure that a variety of label designs can be applied to different application areas and industries.

In using in commodity product, such as retail and consumer goods, Item-Level Tracking has become an automated process in the source manufacturing process or distribution centre. Similarly, if you can use the same way to deal with the label code which is to facilitate the centralization management and quality control.

The cost of the label. RFID tags can range from USD $10 cents to over $ 60, and the price difference is quite large. In general, with the demand increase rapidly and continuously improvement of the technology, the price is getting cheaper in the future. For special labels which need to be applied on to the more rough surface of the product required a special design, therefore the price is relatively higher.

Fifth as part of the overall RFID solution, the choice of labels must be in line with the needs of different businesses. Once the industry understands what content or product should be integrated RFID technology, the selection of the appropriate label can be reduced to a smaller range. The ultimate goal of using RFID tags is to streamline the process and workflow in organisation.